Different types of waste

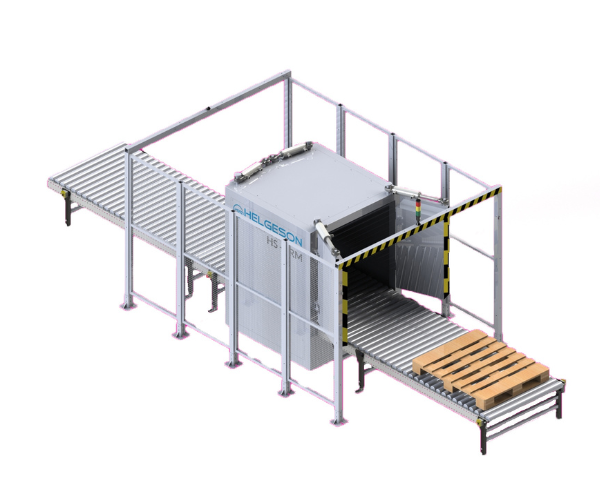

The HS-FRM is a free release monitor to be used with different types of waste like drums, containers and big bags.

It is a chamber shielded from the influence of external natural radiation and consisting of detectors in each of the 4 side panels, ceiling and floor.

This allows to perform a fast and efficient detection and quantification of radiation from the waste present inside the chamber.

- HPGe

- NaI

- Dose rate meter

- Lead shielding of 5, 7 or 10 cm on all side panels, floor and ceiling.

- Cylindrical drums of 200, 400 liters or similar

- Containers with dimensions similar to the Euro palette 120 x 80 x 74 and 120 x 100 x 74 cm (L x W x H).

- Big bags

– Minimum detectable activity of Co-60 and Cs-137 for the densities indicated between 60 and

150 Bq or that ensure a detection of 0.025Bq/g.

– Measurement times of each container in the order of 1-3 minutes for the limits indicated.

– Ability to distinguish different gamma isotopic compositions present in the

residue.

– Ability to identify volumes or areas with residual content different from the rest of the

metered container

– Capability of continuous measurement and analysis of the background and detection of its variability to to be able to make compensations for the measurement of the material.

– Determination of the uncertainty of the gamma activity determined in the measurement,

in accordance with UNE-EN ISO 11929-1:2021.

- Calibration/verification module with dummies.

– Theoretical calibration of the geometry to be measured in addition to the dummies of

Calibration/Verification.

– Database of measurements carried out.

– Isotope Library.

– Library of geometries to be measured.

– Export import of data, preparation of declassification reports.

– Ability to analyze the measures after they have been carried out

– Implementation of different Scale Factors in the final assessment process

- Internal scale indicating the mass of the measured container. The precision is less than 0.5 kg and the maximum mass to be measured of 1500 kg.

- Opening system for entry and exit for measurement in continuous mode, with two automatic shielded motorized doors controlled remotely, equipped with a security system

- Roller Conveyor system automated and controlled remotely

- Security and alarm system, with security stop buttons for the conveyors, entrance and exit doors.

- Safety sensors that detect the dimensions of the object to be measured, in order to prevent damage to the chamber and the waste packages

- Remote control of the measurement process from a control post with fixed computers or laptops that allows both the manual mode and the automatic mode of measurement

- CCTV that allow visualization of the process from the checkpoint.

- Verification and/or calibration dummies

- System control UPS

- System for reading barcodes, QR codes, RFID or similar for visualization,

- Acquisition and management of basic input data of the containers to be measured.

- Laser printer.

Brand

Application

Research, Nuclear/ Radiation Safety